Bio-Gas UNITS > POST-TREATMENT

Biokomp compressor stations include post-compression treatment units, such as cyclone filters, coalescing filters, dryers and chillers with condensate drainers which remove liquids, dirt, particles, and other impurities from the compressed gas. Condensate is removed automatically from the gas and conveyed to the outlet so to be safely disposed.The post-compression treatment solutions can range as specified below:

DEHUMIDIFICATION

Gas refrigerant dryers and water chillers specially designed for operation with air, acid, flammable and toxic gases. Stainless steel heat exchangers with automatic drainers. Dessiccant adsorption dryers with activated alumina, silica gels, and molecular sieves.

HEAT RECOVERY

Economizers and heat exchangers designed to recover the compression heat and make it available to an external fluid. Available in different materials and sizes. Tailor-made systems with different temperature and flow options.

OIL REMOVAL

Ultra-fine oil particulate filters and special activated carbon filters for oil removal up to 0,01 mg/m³, according to ISO 8573 requirements for oil-free gases.

GAS CONDITIONING

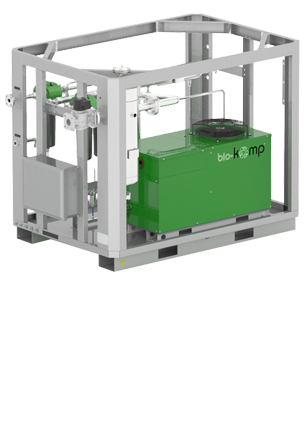

Post-compression gas conditioning skids, designed to control the gas temperature at discharge within a narrow tolerance range. Complete units with oil heat recovery, heat carrier pump, and programmable temperature control logic.